JAGUAR 10 Heating Zone+2 Cooling Zone Lead-free Hot Air Reflow Oven

JAGUAR Desktop 4 Heads Multi-functional Pick and Place Machine

MOQ :1 set

Lead Time :20 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Credit Card,Western Union,Money Gram,Money Order,Pay Pal,Other

Departure Port : Shenzhen

Product details

Supply Ability

- Supply Ability:100 piecesWarranty(Year):1 Year

Packaging & Delivery

- Length:118 cmWidth:108 cm

- Height:88 cmLogistics Weight:240.000 kg/set

- Packaging:1 set

Product Specifications

- Brand name:JAGUAR

- Name:Pick and place machine

- Usage:Chip Mounting

- Machine type:SMT Machine

- Heating mode:No

- No. of heating zone:No

- Total length of heating zone:No

- No. of cooling zone:No

- Termperature control precision:No

- Temperature control mode:No

- Machine control:Control card+PC

Product Description

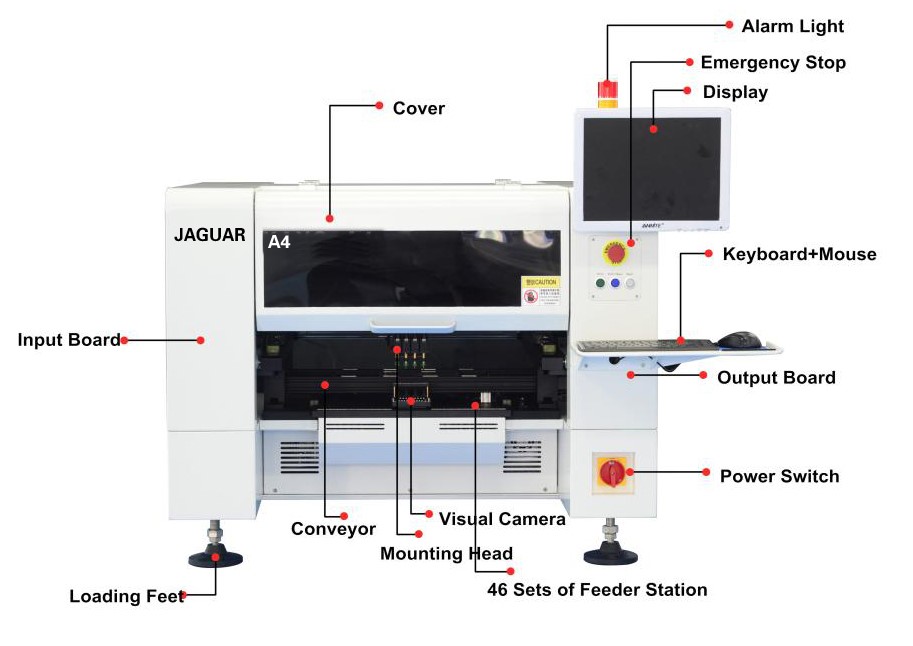

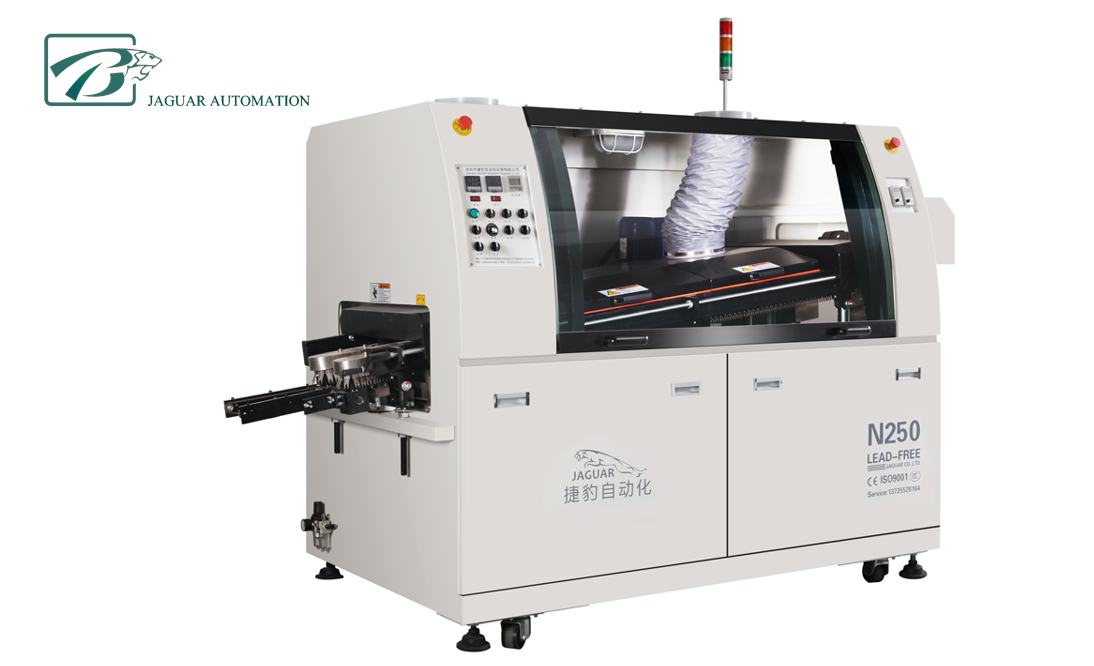

JAGUAR-A4 Desktop Automatic SMT Pick and Place Machine

JAGUAR A4Compact Size Pick and Place Machine is an independent research and developed product according to the actual situation of the welding process, it fills the gaps in the field of the current domestic small wave soldering with it launch, which is very suitable for military enterprises’ office, independent scientific research institutes, small and medium enterprises, small private enterprises, and electronic manufacturer’s lab and R & D center.

Specifications:

Feeder No. | 46 | Product Weight | 240KGS |

Mounting Heads | 4 (No need to change Nozzle) | XYZ Drive Guide Rail | TBI High-precision heavy-duty straight-line guide rail |

Average Power | 600W | ||

Positioning Accuracy | 0.01mm | Motion Drive System | Panasonic High speed DPS driver |

Nozzle Buffering Range | 5.0mm | Operating System | Support Windows XP, Win7 operating system |

Power Supply | 220V, 50Hz | Component Angle | 0~360°, synchronized rotation in motion |

Compressed Air | 0.5-06Mpa | X/Y Running Mode | Intelligent curve acceleration and deceleration linear linkage |

Driving Motor | Panasonic servo motor | ||

Mounting optimization | Program automatically optimization, continue production after mounting completed, no need to wait for resetting | Placement Mode | Manual, semi-automatic, fully-automatic |

Convenient Button | Offline, reset, automatic operation, clear alarm | ||

Nozzle Vacuum Source | High-speed on-off vacuum generator with vacuum damage | Alarm when open the cover | Reducing speed or stop |

Max. PCB Area | 480x300mm | Automated connection | Can automatically connect signal equipment at both end |

XY Max. Movement Range | 556x680mm | Rail Guide Adjusting Method | Manual + Automatic |

Z Axis Max. Movement Range | 20mm | Visual Display | 15" industrial control display ratio 4:3, resolution 1024x768 |

Belt Type Feeder | 8/12/16/24/32mm feeders, stick feeder | Programming Mode | Point-to-point programming, visual programming, PCB file coordinates inputting, etc. |

Max. Mounting Speed | 7000CPH | ||

Average Mounting Speed | 5000CPH (Visual) | Recognition Camera No. | 1x Mark camera, 4x high-speed camera, 1x 500 million pixels high-precision camera |

Dimensions | 1180x1080x880mm | ||

Applicable Mounting Range: Suitable for 0402, 0603, 0805, 1206, LED beads, diodes, transistors, SOT, 40mm*40mm range pin pitch ≥0.3mm QFP, BGA etc. | |||

Advantage:

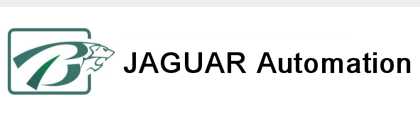

High Precision: Equipped with 6pcs of cameras: 1pc of Mark recognition camera, 1pc of 500 million pixels high precision recognition camera, and 4pcs of synchronous high-speed recognition cameras, could effectively mount 0402-5050 components, LED beads, diodes, transistors, SOP, 40mm*40mm range pin pitch ≥0.3mm chip QFP, BGA etc.

Fast Speed: the max. mounting speed: 7000CPH, average mounting speed: 5000CPH.

Full Automation: With rail guide, could be connected to other machines to achieve inline operation, thus greatly reduce labor costs, only need one person to complete the work.

Strong Stability: Panasonic Servo Motor and Drive, TBI high-precision grinding ball screw rod + heavy-duty linear guide, Japan Vacuum generator, JUKI high-precise nozzles, automatic feeding integrated system and high-configuration IPC - High precision, strong stability, promise 24-hour mounting stably.

About Us:

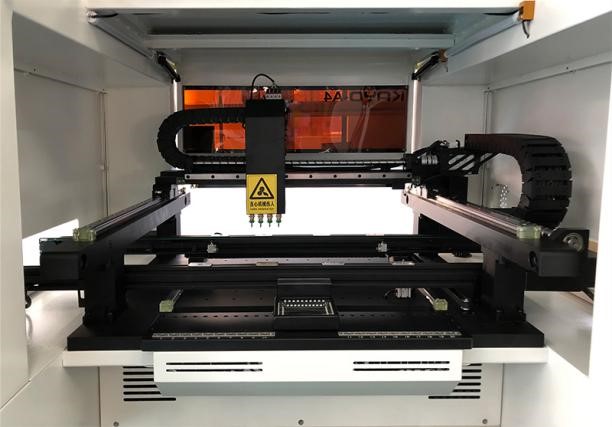

Shenzhen Jaguar Automation Equipment Co., Ltd. is a professional Reflow Oven and Wave Soldering Manufacturer in Shenzhen, China. We focus on SMT and THT Soldering technology for more than 10 years, and our engineers have more than 20 years experience.

We are certified National High-tech Enterprise since 2017, integrated R&D, manufacture, service, trade, all our products have CE certification, our products are widely recognized at our domestic market as well as oversea market.

Our goal is to provide customers with the best service possible and to produce excellent quality products that will meet or exceed your expectations.

Our Factory:

More than 6000 square meters production plant.

More than 20 years experience in SMT automation equipment manufacturing. More than 50 peoples production team, among them

36 mechanical assembly technicians

12 electrical engineers

4 professional QC

Successful Experience:

JAGUAR's customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 600 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

Customer and Feedback:

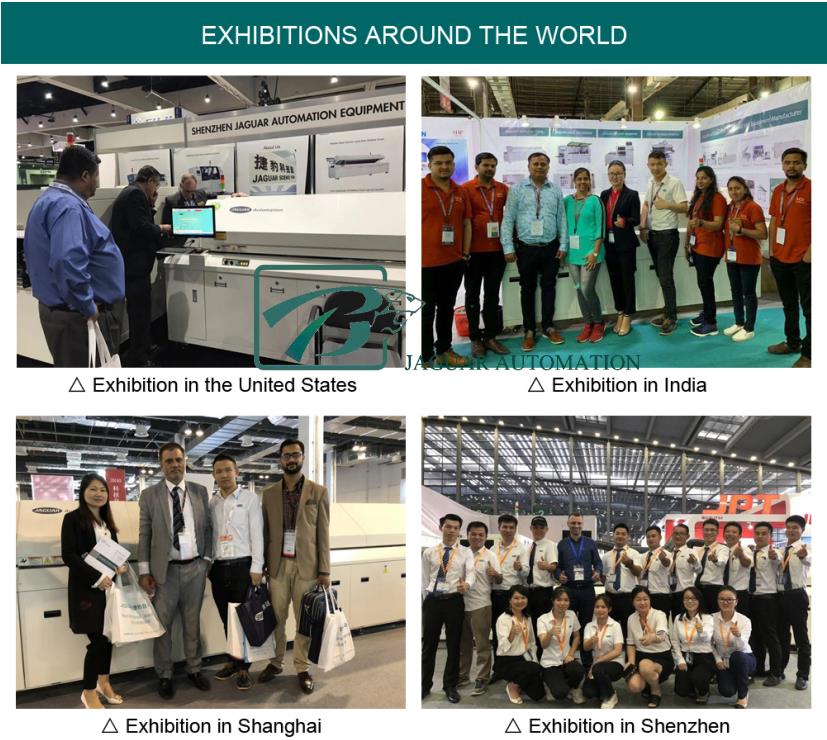

Exhibitions:

Keep attending more than 10 exhibitions and forums each year.

The annual NEPCON and Electronica exhibitions are our regular event.

Participate in 3-5 overseas famous exhibitions regularly every year, like:

IPC Expo in San Diego, US

Electronica in Delhi, India

Electron Tech Expo in Mosco, Russia

WIN Exhibition in Istanbul, Turkey

Our Certificates:

We passed ISO certifications

We are IPC member company

We are National High-tech Enterprise

All the machines have CE and ROHS certifications

Packing and shipping:

What we can do for you?

1. We provide full SMT and THT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT and THT factory setup

5. We can solve any question about SMT and THT

Please contact me if you need any machine!

Best Regards,

Nona Xiao

JAGUAR AUTOMATION

Add.:14th Building,Furong Industrial Zone,Xinqiao Street, Bao'an District, Shenzhen,China

Mobile/Wechat/Whatsapp: 86-13590488442

Tel: 86-755-23316315

Fax: 86-755-29497125

E-mail: sales04@jaguar-ele.com Web: www.jaguar-ele.net

My Linkin: https://www.linkedin.com/in/nona-xiao-74959915b/

You May Like

- Exhibitor

- Gold Supplier

- Trade Assurance

Business Type : Manufacturer,Service,Trading Company,Organization,Exporter,Importer,Wholesaler,Distributor,Agent,Retailer,Sourcing Office,Contractor,Chain Store

Company Location: GUANG DONG

Year Established: 11YRS

You May Like

-

JAGUAR 10 Heating Zone+2 Cooling Zone Lead-free Hot Air Reflow Oven

-

JAGUAR Practical 8 Heating Zone+2 Cooling Zone Lead-free Hot Air Reflow Oven for Auto Signal

-

JAGUAR Pracitical 8 Zones Lead-free Hot Air Reflow Oven for LED Signs Assembly

-

JAGUAR 8 Heating Zone+2 Cooling Zone Lead-free Hot Air Reflow Oven for LED Bulb Assembly

-

JAGUAR Practical 8 Heating Zone Lead-free Hot Air Reflow Oven for Wall Washer Light

-

JAGUAR Practical 3 Preheater Lead-free Wave Soldering Machine

-

JAGUAR 2 Preheater Lead- free Hot Air Wave Soldering Machine for LED Driver

-

JAGUAR Economic 6 Heating Zone+1 Cooling Zone Lead-free Hot Air Reflow Oven for Street Light

-

JAGUAR High Productivity 6 Heating Zone Lead-free Hot Air Reflow Oven for Stage Lights

-

JAGUAR Economic 6 Heating Zone+1 Cooling Zone Lead-free Hot Air Reflow Oven for LED Panel